Menu

We create custom packaging that turns your ideas into reality. With a series of detailed steps, we ensure your packaging meets your expectation. A solution that focuses on enhancing production efficiency, marketing effectiveness, consumer packaging experience and sustainability.

We are dedicated to working together with our customers to bring your great product an advanced and sustainable packaging.

(O2 & Water Vapour Barrier)

(Cardboard/Plastic)

Understanding our customers’ needs and requirements will help us determine the type of design required and the packaging’s success. In this stage, our team will be required to collect some information to work in the right direction and recommend practical solutions.

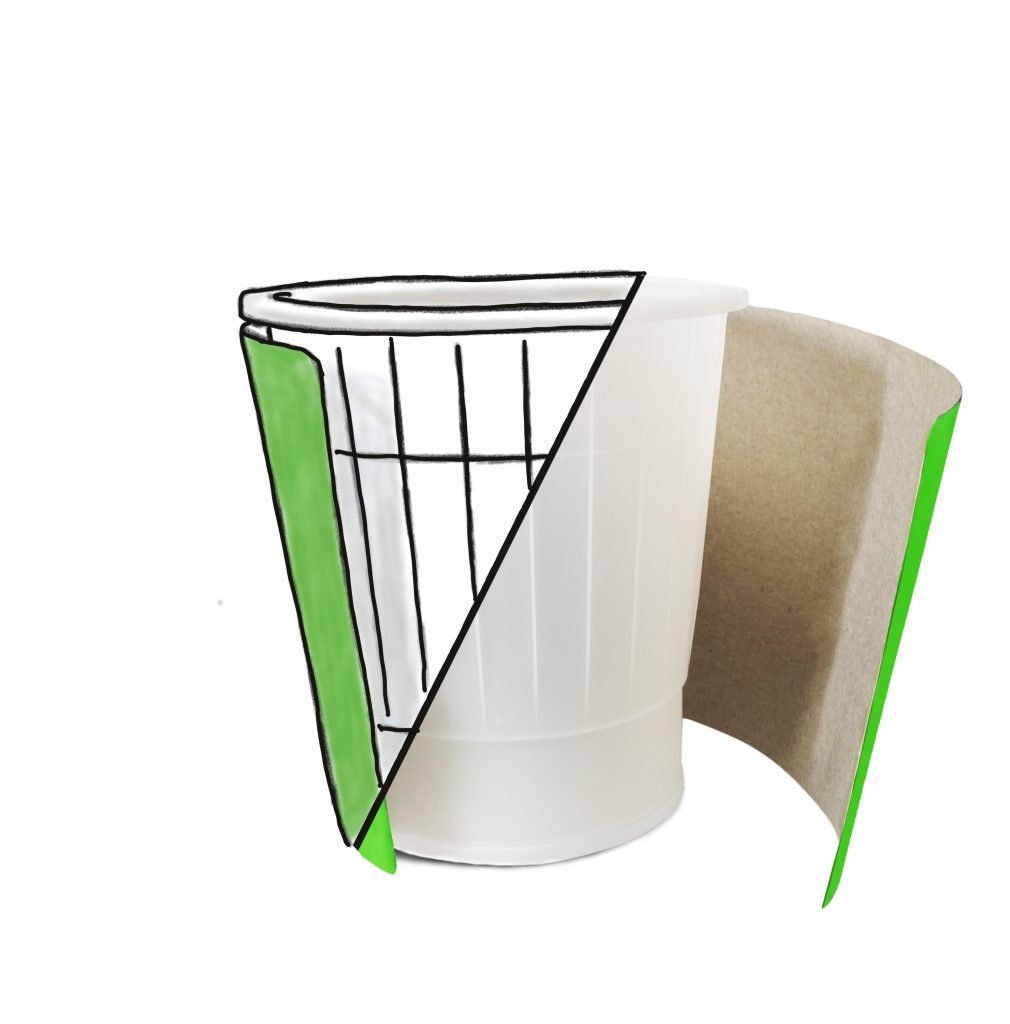

After performing a detailed understanding of the customer’s expectations and the facility, we will then work on sketches and CAD mock drawings to visualise your dream packaging. In some instances, customers provide us with samples or drafts, allowing us to work on it quickly and efficiently.

After the approval of our drafts, we will then work on the approved draft details. We understand that not everyone will be able to picture the actual look and feel of the packaging. Hence, we offer our free 3D printing service for our customers to have an actual feel of the packaging. We recommend customers to fill their product and test its volume to verify if headspace is sufficient.

With the final design approved, we will be able to commence with commercial mould fabrication. Small projects and large projects are prioritised similarly, and with the understanding of the annual volume, we will be able to recommend a suitable mould size required for the project.

Enhancing packaging experience – With your new packaging, we want to help you build a story around your product which helps translate to sales by having more significant customer engagement. Enhancing your overall packaging experience from aesthetic to functionality is our main aim.

Combi-Pack is one of the leading and award-winning manufacturers of high quality and innovative plastic food packaging in Malaysia.

Custom packaging means tailoring your packaging to suit your product, brand and production line.

Custom packaging allows your product to stand out from the crowd. A unique and wholesome customer experience plays a vital role in selling your food product. Well thought out packaging greatly impacts a consumer’s impression of the quality, brand, and company.

For example, Coca-Cola always designs its bottle in an almost similar shape. As consumers have registered this design in their minds, it is useful for future marketing. Custom packaging is also required to suit your production line, not just for marketing purposes but also to enhance efficiency or solve particular problems.

You can customize anything from a specific height, dimension, shape, and area where labels and graphics are placed. You’ll be able to choose whether to go for the Foil Sealing option or Tamper Evident. With this customized packaging, you’ll be able to stand out on market shelves or even achieve the special function you’re looking for.

We start by fully understanding your product needs and requirements. Then, we translate them into design sketches and recommendations. Once the design is approved, we will create a prototype and determine the best and most cost-efficient way to proceed with production based on your design and required volume.

Contact us today to discuss your product’s specific needs.

Combi pack 2023 © All rights reserved. Web design by Walk Production